Some of the glass terminology that we use at JIT will help you to determine the proper glass edge finish you should consider requesting. Glass Cut Edges serve several purposes depending on the application you are using it for. Whether it is for strength, safety or cosmetic reasons, JIT Companies can provide you with the glass cut edge you need.

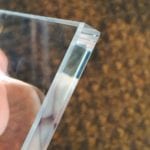

Clean Cut Edge

Common Glass Cut Edges

CLEAN CUT EDGE is just that. The process is simple as a glass cutter is used to score the surface of the glass to size or shape. This scoring action produces a small fracture on the surface which creates a weak point for the break to follow the scoreline. The resulting edge is very sharp and can easily cut unprotected hands. This type of edge is also susceptible to “clam shelling” which is caused by the glass edge coming in contact with itself or another hard material. From a process standpoint, clean cutting is usually followed by edge seaming.

Seamed Edge

SEAMED EDGE is a process in which an abrasive diamond wet belt is used to slightly “Kill” both edges of a clean-cut piece of glass. This produces a safe edge to handle with your bare hands and also helps increase the strength of the glass. During the scoring process, small micro-chips were created on the scored surface and each one of these chips is a weak point in the glass and could cause breakage if the glass were to be flexed during handling. Edge seaming removes these “micro-chips” from the sharp edges of the glass which in turn reduces the defect rate. At this point, the glass can be installed into suitable frame work without the need of additional processing.

Waterjet Edge

WATERJET EDGE is produced with our ultra-high pressure waterjet cutters using a fine abrasive that produces a smooth matte finish on any thickness of glass. This process allows for extreme precision when tight tolerances are required in a finished part. Depending on the final application, this is usually followed up with a polished edge.

FLAT EDGE (POLISHED or MATTE) finish is a process that utilizes high speed grinding and polishing wheels in a specialized machine that produces the ultimate edge finish to glass. The resulting edge can have a crystal clear or matte finish with arrised edges that produce the desired look when all of the edges will be visually exposed. This also gives the glass its maximum strength in its annealed form because all of the edge imperfections have been removed from the previous processes.

Flat Edge

You now have a basic understanding of some of the common glass edge finishes JIT Companies can provide for your project: Clean Cut Edge, Seamed Edge, Waterjet Edge, and Flat Edge. When you are ready to learn more about glass, contact JIT Companies for more detailed information by calling us at 507-326-5240. You’ll be glad you did!