There are many facets and terms that are used in the metal finishing industry. Many times a single term can have a different meaning to each individual which could possibly lead to a misunderstanding at some point in the finishing process. Being aware of the terms that your metal finisher uses will help everyone be on the same page and talk the same language. The terminology below is used by everyone at JIT Companies.

To start, JIT specializes in straight-line metal finishing. Not to be confused with an automated “time-saved finish”, JIT’s process provides a “True” linear grain direction that is produced by our “Metal Artisans”. A “time saved finish” imparts a wavy grain pattern on the metal surface during processing. This process can be faster and sometimes less costly but the visual aspects of the finished part may not be desirable to the end user. JIT’s Architectural Finish is what is most desired by industries that we serve. Mechanically grained and polished surfaces undergo a series of steps with material specific abrasives until the required surface finish is achieved. Let’s take a look at the available finishes and a brief description of each that are available at JIT Companies.

Metal Finishing Terms & Finishes Available at JIT Companies

#3 GRAIN FINISH

This starts as a very coarse grinding to remove mill scale and pits from heavy plate, structural tube, angle, etc. from the material surface. Depending on the configuration or profile of the material, this will be accomplished with a variety of cutting discs and tools using progressively finer abrasives. The final step is a linear grain finish to blend all surfaces. The final abrasive used for this finish will be 60/80 grit.

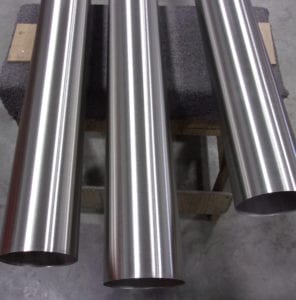

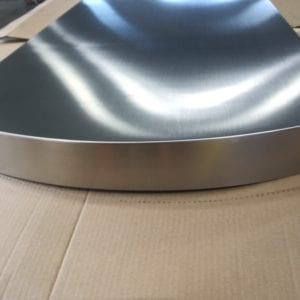

#4 ARCHITECTURAL GRAIN FINISH (Also referred to as Brushed, Directional, Mechanical Polished or Satin Finish)

This finish is the most commonly requested (and pictured above) as the sanding or grain lines are uniform and directional in appearance. The final abrasive used for this finish will be 120/180 grit. JIT’s standard finish is a #4/120Grit.

#4 DAIRY OR SANITARY FINISH

This finish is commonly required for processing stainless steel for the food and medical industry. All surface defects that would provide areas for potential bacterial growth must be removed. The final abrasive used for this finish will be 180/220 grit.

#6 GRAIN FINISH

This will have the same characteristics as a #4 finish, however the final abrasive used for this finish will be 220/280 grit.

#7 GRAIN FINISH

This finish will have an Ultra-smooth grain with a bright appearance and is considered a pre-polished finish for chrome plating. It can be color buffed with polishing compounds to enhance the surface brightness. Parts will still have evidence of a grain finish. The final abrasive used for this finish will be 320 grit.

#8 MIRROR FINISH

This metal surfacing finish will have a very Ultra-smooth grain with a bright, somewhat clear reflection with a very light haze. Cloth buff wheels and color buff polishing compound are used to achieve a mirror quality surface, however the final finish will also depend on the quality of the metal being polished (If you are looking for a “True” mirror finish, this material is usually available from a metal supplier depending on the gauge and profile of the material).

If you have any questions related to these straight-line metal finishing terms or need more clarification on what JIT can do for you, please contact us and we would be more than happy to assist you. Call us at 507-326-5240 for further information or request a straight-line metal finishing quote here.